Tooling Documentation

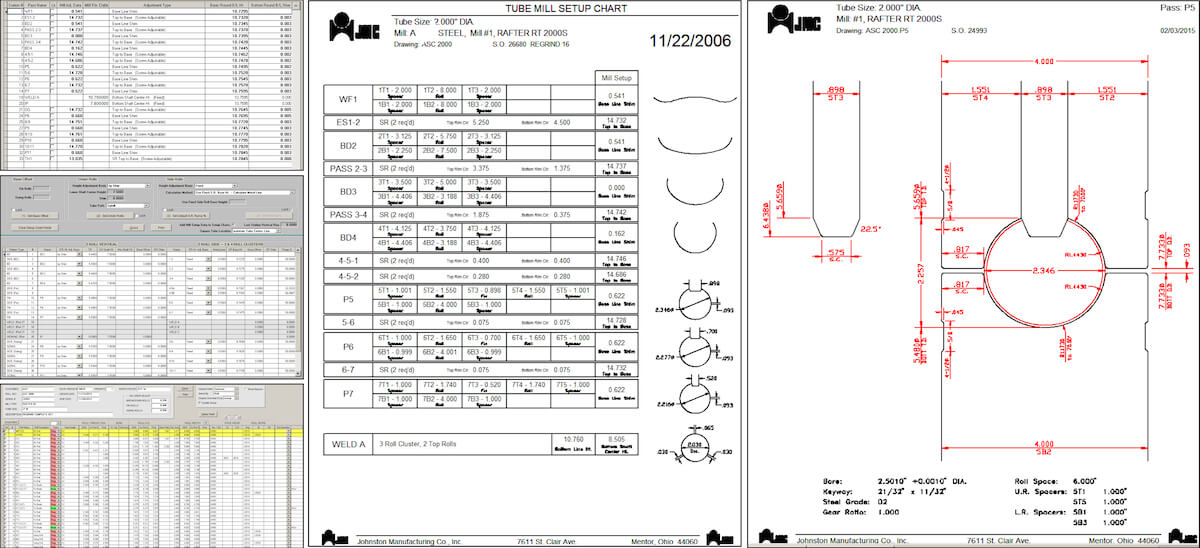

Our system generated tooling records and documentation follow your tooling throughout its lifespan. System generated means all tooling design and mill set up charts are created and updated accurately and without human error.

A tube roll set can have a functional life span of five to thirty five years. During this period many regrinds, individual roll replacements, and/or design modifications will occur.

As changes are made or diameters drop when tooling is reground, historical records are kept in our database and all new documents generated will reflect these events. For example, after regrinds, our set up charts are re-generated, saved, and a copy delivered with the tooling. They now give new mill set up data. If breakdowns, fins, and/or sizing groups are reground at different intervals the new set up chart will show the correct metal line shims and/or side roll “top to base” height adjustments for each pass in each group. Once your mill is locked into our database this complex and critical information is updated automatically and is no more than a mouse click away when needed.

A JMC Rolls exclusive is our tube metal line height report. This print out, based on current regrinding data, provides real time metal line height data for your product at each pass location. This data is especially helpful when reshaping to squares and rectangles or as verification that there are no errors in tooling design or mill station data. Again, software implementation of all design and mill set up documents means accuracy without human error. Only a full service roll shop like JMC Rollmasters can provide the documentation required for your tooling verification programs.