Strip Width Recommendations

Improper strip widths can cause failure of the welding process, fin blade breakage or mill drive overloading. Start-up strip widths are critical with the implementation of new tooling. Strip width choices can vary depending upon welder type, mill configuration, tooling design, product specifications, and even set up and operating practices. At JMC Rollmasters we consider all of these relevant when estimating strip widths.

The strip width calculations within our tube roll design software have allowances for all of these factors. It incorporates true neutral axis positioning calculations based on your actual tooling design. And, once we pin down your specific variables, we can do the following.

- We can more accurately estimate your strip width for a new tube size.

- We can evaluate your existing strip widths and locate sizes where you might add to or reduce strip widths to improve performance and product quality.

FOR STRIP WIDTH SOLUTIONS BASED ON STANDARD MILL AND TOOLING FUNCTIONALITY, CLICK THE RED CALCULATOR BUTTON AT THE TOP OF THIS PAGE AND USE OUR ONLINE STRIP WIDTH CALCULATOR

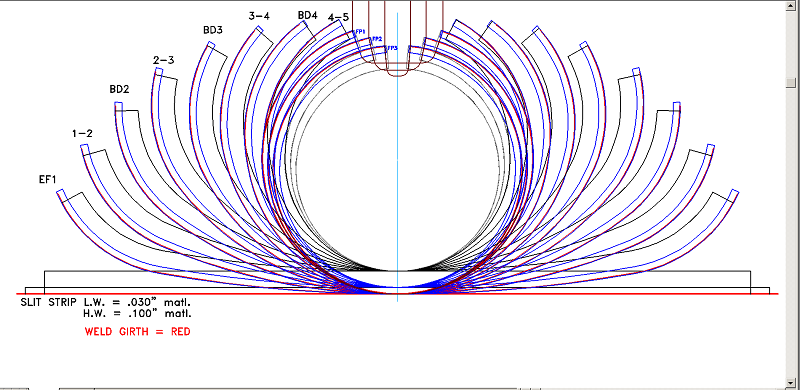

THE ABOVE GRAPHIC ILLUSTRATES THE DIFFERING GROW RATES OF LIGHT AND HEAVY WALL STRIPS RELATIVE TO THE FIXED WELD GIRTH IN RED